A number of Saudi Arabia’s economic sectors are upgrading and industrializing quickly. Modern industrial machinery solutions are essential to enabling increased output, effectiveness, and quality. The main advantages of cutting-edge machinery for Saudi Arabia’s diverse sectors will be covered in this blog.

Increased productivity

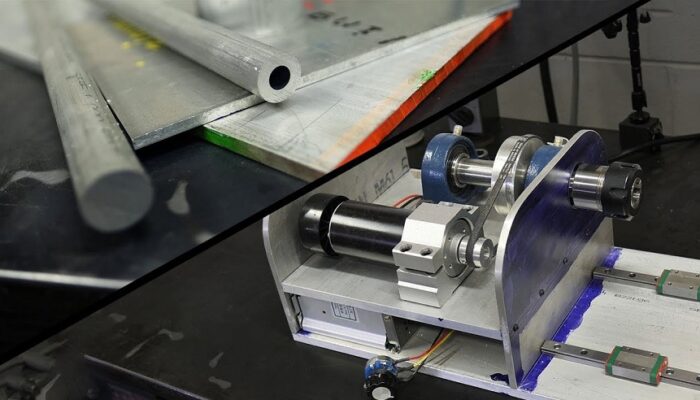

Robotics, CNC machines, programmable logic controllers, and autonomous guided vehicles are examples of advanced technology that can do labor-intensive, repetitive tasks far more quickly than people. This boosts productivity tremendously and enables businesses to employ fewer staff to perform the same amount of labor. Additionally, automation guarantees uniformity and lowers human mistake rates, both of which increase production. The increased efficiency allows companies to meet growing customer demands more effectively without expanding their workforce. Automation streamlines operations and optimizes processes so businesses can maximize output while minimizing costs and errors. Overall, advanced manufacturing solutions boost a company’s productivity to new levels.

Reduced operating costs

Sophisticated automated systems need less oversight and human involvement. One of the main running expenses is labor, which is decreased as a result. Additionally, automation increases productivity, which lowers the cost of utilities like gasoline and electricity. Compared to people, machines are less maintenance-intensive and have a longer lifespan. These elements all contribute to reducing a company’s overall operating expenses. Robots and other automated technologies work continuously without breaks, overtime pay, or benefits. Their consistent performance eliminates unpredictable human factors that can increase costs. Over time, the savings from reduced labor and steady output adds up significantly to the company’s bottom line.

Improved product quality

Compared to human labor, machines are able to do jobs with a very high degree of consistency and accuracy. Systems for automated quality inspections also find flaws early on. This guarantees that goods fulfill exacting quality requirements. Reputation and client satisfaction are enhanced by consistent good quality. Additionally, it lowers the price of reworks and faulty goods. Automation eliminates variability between individual human performances, ensuring uniform dimensions, properties, and specifications in every item. Precision manufacturing through robotics and computer controls results in superior quality that builds customer loyalty. The reputation for quality products allows companies to demand higher prices and expand into new markets. Overall, automation strengthens a brand by delivering excellence in every unit.

Increased flexibility

Modern gear is incredibly adaptable and adjustable. Production lines can easily reconfigured to produce various product variations or to move across product families. As a result, operations are more adaptable and sensitive to shifting consumer needs. Businesses are able to quickly introduce new goods, modify manufacturing to suit needs, and change volume requirements. Automated systems allow for fast and low-cost product changes through easy programming adjustments. Machines can seamlessly transition between discrete tasks and mass customization. The flexibility to respond promptly to market trends helps companies capture more demand and gain an edge over static competitors. Overall, automation makes operations highly versatile for unpredictable modern markets.

Enhanced workplace safety

Automated systems eliminate risks from hazardous, strenuous and repetitive tasks. Robots can work in confined spaces and handle hot, toxic or heavy materials safely. Automation reduces accidents and improves occupational safety. It protects workers from injuries and associated medical and insurance costs. The working environment becomes much safer with advanced machinery. Robots do not grow fatigued like humans, decreasing human errors. Automation also prevents ergonomic issues by removing the need to lift or carry heavy loads. With fewer safety incidents, companies avoid costly OSHA fines and maintain a strong safety record. Overall, automated factories create a healthier workplace for employees.

Improved traceability and transparency

Industrial IoT solutions and analytics provide real-time visibility into operations. Data from sensors tracks production parameters, asset performance, energy usage and other metrics. Issues can be detected proactively. Managers have access to accurate production reports and traceability records for regulatory compliance and quality certifications. This level of transparency boosts efficiency. The detailed audit trail supports continuous improvement efforts. Connected devices facilitate rapid problem-solving by pinpointing weak points. Advanced monitoring tools give leadership comprehensive insights for strategic planning. Overall, digitalization brings unprecedented insight that strengthens management and accountability across the enterprise.

Skills enhancement

Working with advanced machinery requires new technical skills like programming, robotics, automation, predictive maintenance, data analytics etc. This upskills the workforce and makes them more employable. It also attracts young talent interested in cutting-edge technologies. Over time, such skills will be crucial for industries to stay competitive globally. Employees receive extensive training on operating automated workcells and digital systems. This boosts their qualifications and career prospects while benefiting their companies. As automation permeates more sectors, retraining programs help reskill displaced workers for high-demand roles. Overall, embracing Industry 4.0 principles develops a technologically proficient labor pool ready to support advanced manufacturing.

Supports Saudi Vision 2030

Automation is a key enabler for realizing the goals of Saudi Vision 2030 which aims to diversify the economy and reduce dependence on oil. It helps boost productivity and competitiveness of domestic industries, attracts foreign investments, creates high-tech jobs and accelerates the development of priority sectors identified in the vision like manufacturing, mining, logistics etc. Advanced machinery plays a vital role in transforming Saudi industries.

Environment protection

Automated systems are more energy and resource efficient than manual methods. They reduce waste, emissions and environmental footprint of operations. For example, computer controlled machines optimize material usage with very little scrap. Electric vehicles and robots replace fuel guzzling equipment. Automation supports Saudi Arabia’s green initiatives and sustainability targets.

Job creation

While automation may replace some repetitive jobs, it also creates new high-skilled jobs in machine operation, maintenance, mechatronics, robotics, programming, quality control, logistics etc. Every advanced machinery project requires mechanical, electrical and software engineers along with technicians at different levels. It also boosts demand for ancillary industries supplying automation components and solutions. On the whole, advanced manufacturing stimulates the economy and generates new employment opportunities.

Conclusion

Advanced machinery brings tremendous benefits to Advanced Machinery Solutions in saudi arabia through higher productivity, lower costs, improved quality, flexibility, enhanced safety, transparency, skills enhancement, economic diversification, environmental protection and job creation. Automation plays a pivotal role in Saudi Vision 2030 by transforming priority sectors. It gives domestic industries and edge in global competitiveness. Overall advanced machinery solutions are crucial for continuous progress of the Kingdom.